From Industrial Waste to Alternative Fuel: The Crushing and Sorting Technology Revolution

Driven by the global energy transition and the dual goals of carbon neutrality, the resource utilization of industrial waste is shifting from a “cost burden” to a “value blue ocean.” Among these initiatives, refuse-derived fuel (RDF) and solid recovered fuel (SRF), as efficient substitutes for fossil fuels, have become critical leverage points for high-energy-consuming industries such as cement and power generation to achieve green transformation. The starting point of this process relies on an efficient and intelligent industrial waste crushing and recycling line.

RDF&SRF

1. Refuse-Derived Fuel (RDF)

Refuse-Derived Fuel (RDF) is a mixed fuel produced from various non-recyclable solid wastes, primarily used for power generation and heating. En los últimos años, to reduce carbon emissions during combustion, the composition of RDF has been continuously optimized: the proportion of plastics is gradually decreasing, while the share of biomass components is correspondingly increasing.

2. Combustible sólido recuperado (SRF)

Combustible sólido recuperado (SRF) is a high-calorific, homogeneous fuel produced through refined processing. Its main sources are high-calorific wastes, such as plastics, that are difficult to further recycle. Due to its stable combustion characteristics, SRF has become a key alternative to traditional fossil fuels in the global cement industry.

3. Comparison Between SRF and RDF

Both SRF (Combustible sólido recuperado) and RDF (Refuse-Derived Fuel) fall under the category of solid alternative fuels. Their main differences lie in the level of refinement and quality control:

RDF is a preliminary processed waste fuel with significant variations in composition and calorific value.

SRF, por otro lado, is a high-quality fuel produced through more precise sorting, Procesando, and strict quality control. It is typically derived from industrial waste, characterized by high calorific value and low impurity content, making it suitable for high-efficiency combustion.

Both SRF and RDF can be used in applications such as cement kilns and industrial furnaces. Sin embargo, SRF adheres to stricter standards, offers more consistent quality, and is considered a refined and upgraded version of RDF.

Yo. SRF (Combustible sólido recuperado)

Source: Industrial and commercial waste (p ej., waste plastics, wood scraps, textile remnants).

Processing: Fine crushing, ordenación, impurity removal, with strict quality control.

Características: Alta calidad, high calorific value, uniform composition, low impurities, and environmental cleanliness.

Aplicaciones: Cement kilns, high-energy-consuming industrial furnaces, meeting stringent efficiency requirements.

II. RDF (Refuse-Derived Fuel)

Source: Municipal solid waste (MSW).

Processing: Basic sorting, crushing, y secar, with a lower level of refinement.

Características: Relatively unstable quality, potentially lower calorific value.

Aplicaciones: Incinerators, certain industrial furnaces, serving as an alternative to landfill disposal.

III. Core Differences

Source: RDF is mostly derived from domestic waste, while SRF primarily originates from industrial waste.

Processing: SRF is a refined and standardized product, whereas RDF is more akin to preliminary processing.

Quality: SRF is a high-quality, high-calorific fuel, essentially a “refined” version of RDF.

Aplicaciones: SRF meets higher energy efficiency requirements and is used in cement kilns, while RDF has broader applications with relatively lower requirements.

Start with crushing

The everyday items we once considered waste—paper, packaging bags, plastic bottles, and industrial byproducts such as leather scraps, used tires, and wood—are no longer an environmental burden. They are being collected, crushed, sorted, and transformed into valuable raw materials for alternative fuels; becoming clean energy sources that replace coal in industries such as cement and power generation, directly reducing reliance on fossil fuels and carbon dioxide emissions.

When waste is given a new purpose, it leaves behind its “end-of-life” status and enters a circular value chain of regeneration. This is not only a transformation of materials, but also a reshaping of a new value chain, moving from “desperdiciar” a “empowerment.”

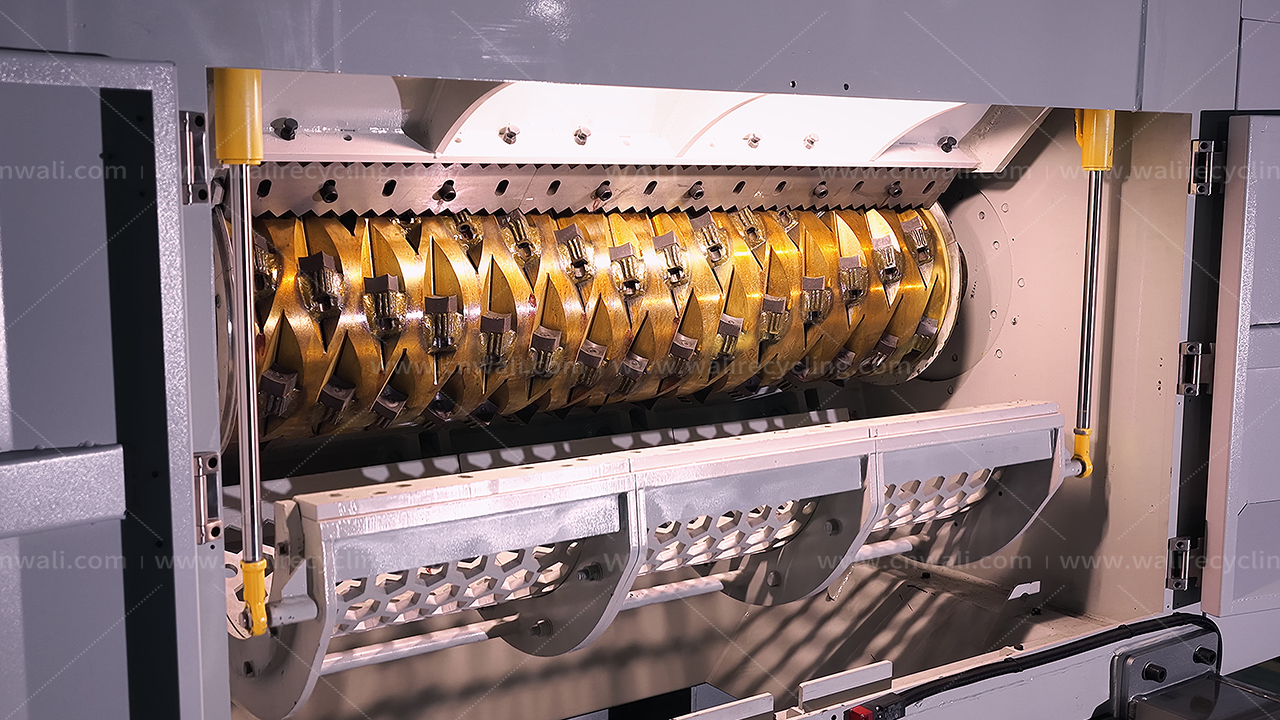

We deeply understand that the recycling process begins with efficient crushing. By reducing the size of materials, separating their components, and preparing them for reprocessing, crushing lays the foundation for sustainable recycling.

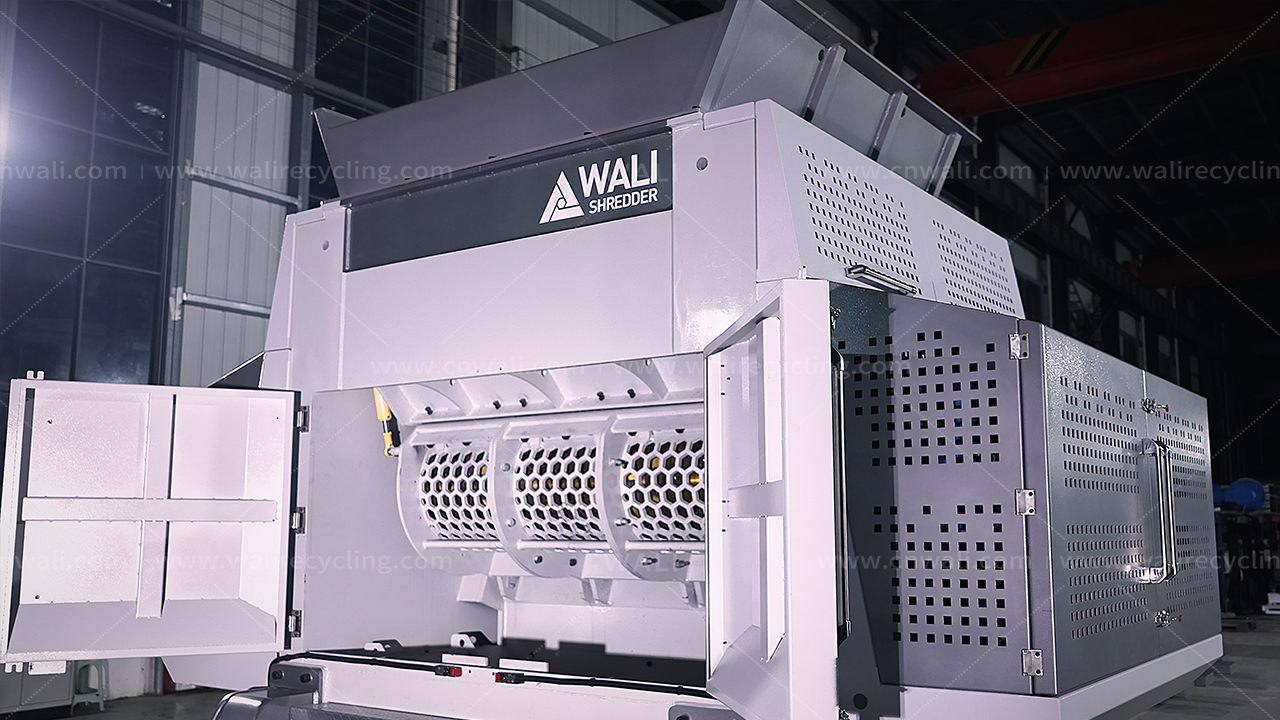

Under Wali’s technology system, specialized and modular production lines for “crushing + fine sorting” provide critical preprocessing assurance for the subsequent production of high-standard SRF alternative fuels or RDF fuel rods.

in RDF&SRF plant

In the production process of RDF/SRF, crushing and sorting are the core stages that determine the final fuel quality and utilization efficiency.

The system we employ is based on ambient-temperature mechanical and physical technologies, achieving material size reduction and component separation through purely physical means, with no need for melting or chemical treatments throughout the process, ensuring a clean process and controllable energy consumption.

All processes and equipment configurations can be custom-designed and integrated based on the client’s specific material characteristics, production capacity requirements, and end-product needs, to achieve optimal resource recovery and economic benefits.

with WALI

Wali’s industrial waste resource recovery solutions have been successfully implemented in numerous countries and regions worldwide. With industry-leading crushing and sorting technologies at its core, we provide clients with end-to-end services encompassing project planning, equipment supply, and installation commissioning. We efficiently address industrial waste disposal challenges while helping enterprises transform waste into stable and reliable green energy, achieving a dual enhancement of environmental and economic benefits.

-END-