The Features of Metal Hammer Mill

Introducción

Introducción

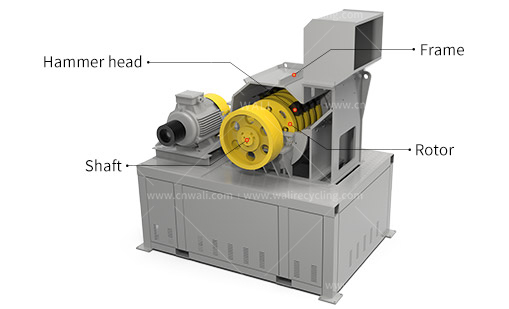

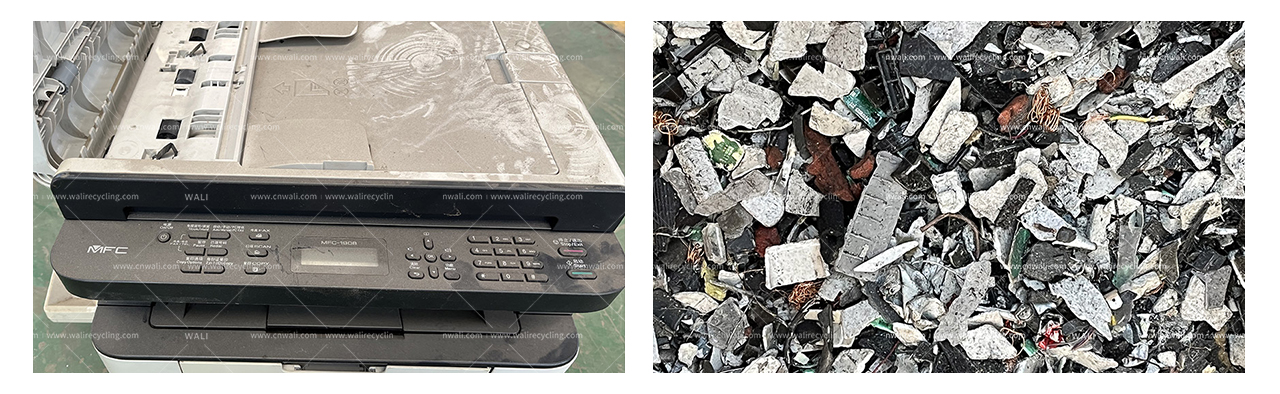

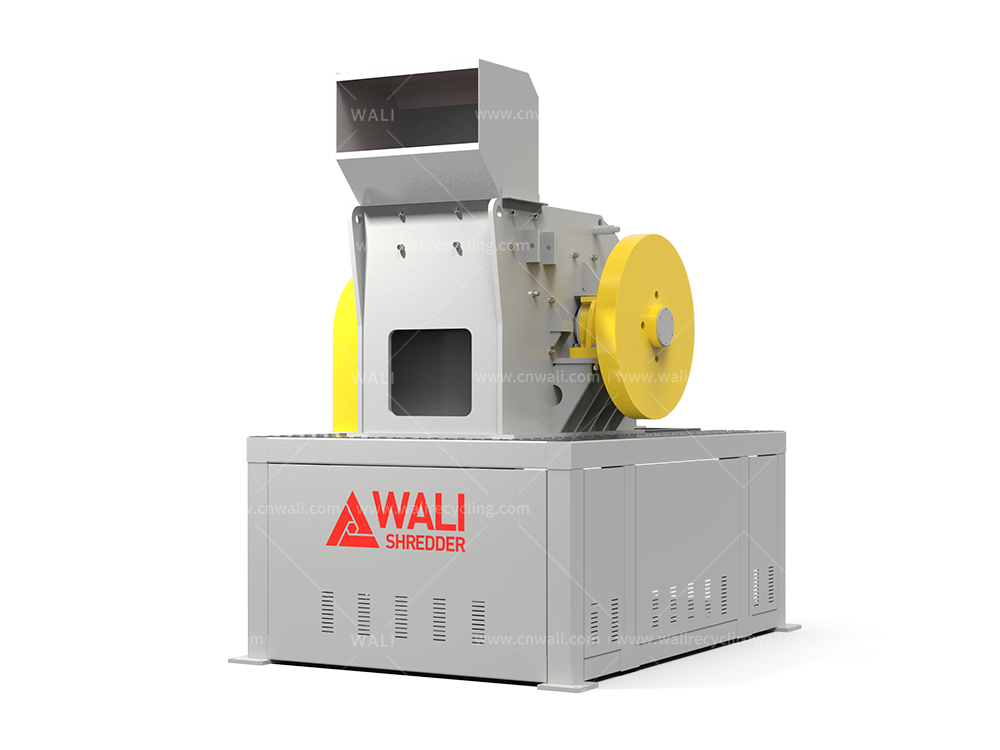

The metal hammer mill is an highly efficient equipment designed to crush solid and hard materials with the aim of reducing size or separating the metal and subtances,achieving high density, high purity products.

The main working part of hammer mill is hammers mounted on the rotor. By striking the materials with swinging hammers, the materials after being fed are effectively grinded and shattered at high speed in the crushing chamber. After output particle size reaches the size of screen, materials will be discharged. El molino de martillos se aplica comúnmente para una amplia variedad de materiales,como el vidrio, batería de litio, Chatarra, Residuos electrónicos, electrodoméstico, etc..

Ventajas

In the solid waste recycling industry, the metal hammer mill has great advantages

1.High alloy steel

The main components of this machine mainly made of high alloy materials with high bearing capacity and strong stability, making machine more wear-resistant, impact-resistant and be robust and reliable, as well as spaning long life.

2.Rotor

The rotor is composed of a spindle, a disc, a shaft pin and a hammer head. Wali metal hammer mill can be replaced not only with a hammer head, but also with a blade. Supports custom shapes and sizes on demand.

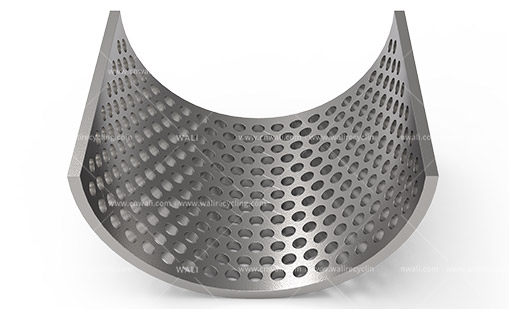

3.Pantalla

Equipado con una pantalla,Podemos controlar el tamaño de la salida eligiendo la pantalla deseada para adaptarse a diversas necesidades, and screen is designed to be easy to move, y limpie y reemplace.

4.Sistema de sellado

El sistema de sellado ofrece un sellado estable y seguro en condiciones difíciles, mejorando la resistencia del sistema a la corrosión y haciéndolo adecuado para entornos hostiles.

5.Sistema de control PLC

Los principales componentes eléctricos del molino de martillos son marcas de confianza como Siemens y Schneider. El sistema de control PLC puede realizar monitoreo en tiempo real, Alarma anormal, Diagnóstico remoto y análisis de datos.

6.Low maintainence cost

Sturdy structure, robust design and quick access to wear parts for optimal performance. This feature significantly reduces maintenance time, enhancing operational efficiency and minimizing downtime.

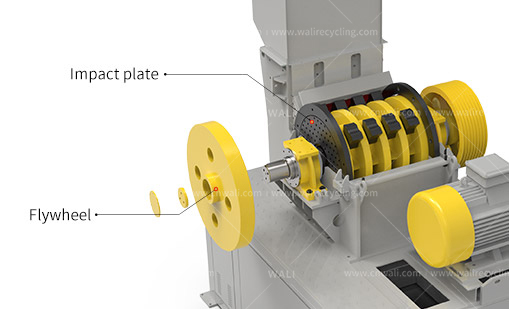

7.Volante de inercia y placa de impacto

The flywheel is mounted on the side of bearing and impact plate is installed in the crushing chamber. These special designs ensure the soomth operation of machine and effectively reduce the impact on the motor during the crushing.

Aplicaciones

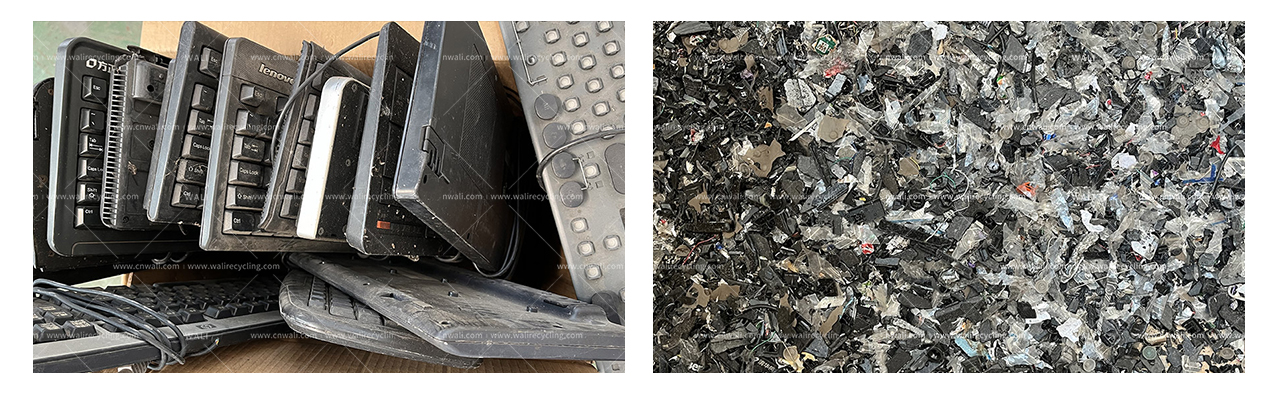

Metal hammer mill is a ideal solution for procision grind, sieving, collection of various waste,including but not limited to following industries

+Chatarra: Chatarra ferrosa, chatarra de aluminio, Metal mixto, bobinas de cobre, Bobinados de cobre, acero, UBC, chapa metálica, etc..

+ Residuos electrónicos: Radiadores, Motores eléctricos, Materiales hidráulicos, transformador, Alternadores, cables eléctricos, Pequeños electrodomésticos, etc..

+ Coche de chatarra: cárter, Unidades de control del coche, Pilas y acumuladores, Vehículos de demolición, bujía automotriz, etc..

Conclusión

The metal hammer mill plays an important role in waste treatment,resource recovery and material crushing with its high efficiency, stability and strong adaptability. As a manufacturer in solid waste recycling industry with more then ten years, WALI team have extensive experience and advanced technology to cater for customer any requirements.

Introducción

Introducción