TDF Tyre Recycling Line

I. Why Recycle Tires?

a. Massive Volume of Waste Tires

With the rapid development of the automotive industry, the number of waste tires continues to grow. Globally, approximately 1 billion waste tires are generated annually. These discarded tires occupy vast amounts of space, and improper disposal causes severe environmental harm.

b. Tires Are Non-Biodegradable

Tires are primarily composed of rubber, steel wires, and fibers, making them highly resistant to corrosion and degradation. If directly landfilled, they can take hundreds of years to decompose fully.

c. Pollution from Incineration

Burning waste tires releases toxic gases, such as sulfur dioxide, posing serious threats to air quality and human health.

D. Resource Waste

Waste tires contain valuable recyclable materials (per esempio., rubber, carbon black, steel wires). Simply discarding or burning them squanders these precious resources.

II. WALI TDF Tire Recycling Solution-Transforming “Black Pollution” into High-Value Resources

By adopting TDF (Tire-Derived Fuel) production technology, these ‘black pollutants’ are given new life through intelligent tire recycling production lines. They are transformed into high-value resources, offering a win-win solution that benefits both environmental protection and economic efficiency

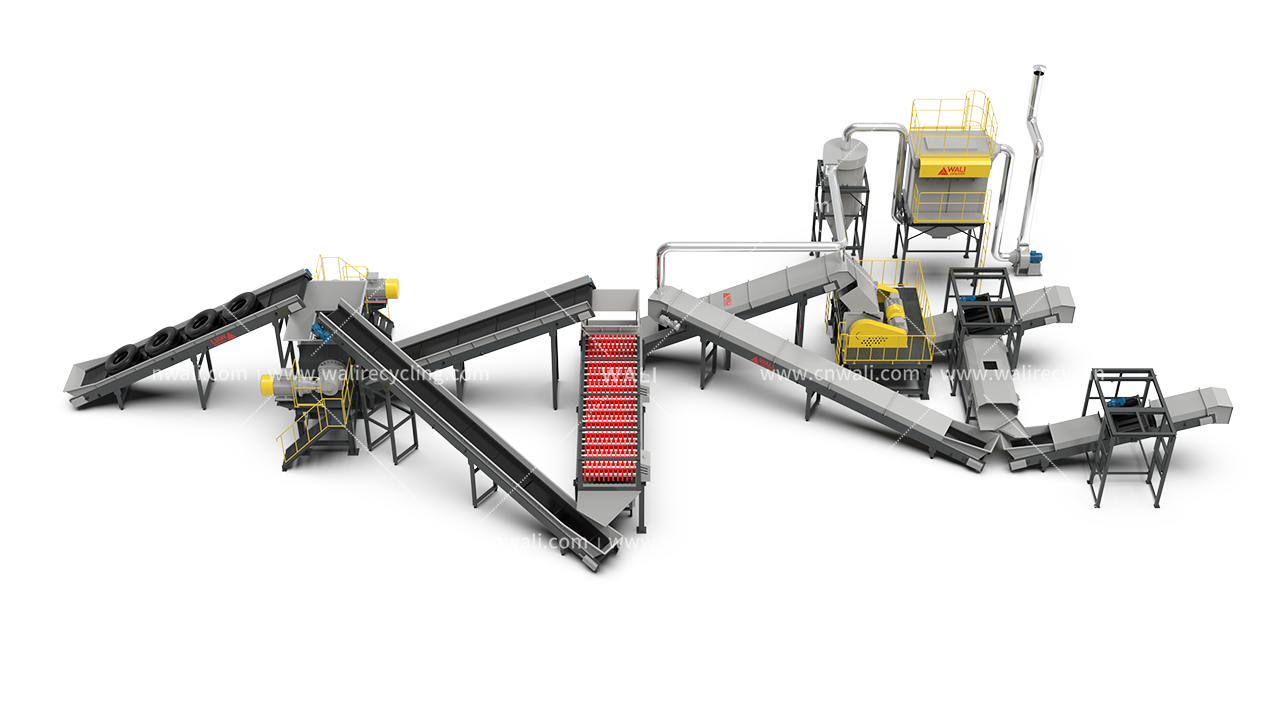

WALI TDF Tire Recycling Line – Cutting-Edge Technology, Exceptional Efficiency

This system is designed to automatically separate rubber, steel wires, and nylon fibers, ensuring maximum resource recovery.

1. Dual-Shaft Shredder

Tires are fed via a belt conveyor into the dual-shaft shredder for initial crushing. The shredded material then moves to the star-screen separator.

2.Star-Screen Separator

The material is divided into oversized and undersized fractions:

Oversized rubber chunks are returned to the shredder for further processing.

Undersized material proceeds to the steel wire separator.

3.Steel Wire Removing machine

The undersized material is transported via an enclosed belt conveyor to the steel wire rremoving machine. A magnetic separator extracts the steel wires, leaving pure rubber material.

4.Vibrating Feeder

The rubber undergoes grading:

Oversized rubber is sent back for reprocessing.

Properly sized rubber passes through another magnetic separator to remove residual steel wires.

5.Cyclone Collector

Efficiently captures nylon fibers and other impurities during separation.

6.Dust Removal System

Ensures a clean and eco-friendly production process, eliminating secondary pollution.

The TDF recycling line achieves the resource utilization of waste tires, reducing landfill dependency while lowering reliance on fossil fuels. Different production lines may adjust process details (per esempio., particle size or desulfurization) based on end-user requirements.

III. Output After Tire Processing

IV. End Applications

Rubber Products: Retreaded tires, shoe soles, sealing rings.

Construction Materials: Rubberized asphalt roads, sports tracks, anti-vibration mats.

Energy & Chemical Industry: Pyrolysis oil (alternative fuel), carbon black (for coatings & tire manufacturing).

V. Conclusione

Waste tires are not the end—they are the beginning of a circular economy!

Tire recycling is not just an environmental necessity but also a critical step in resource management and economic transformation, playing a vital role in achieving sustainable development.

Our tire recycling system not only ensures high-efficiency recovery but also offers customized solutions tailored to customer needs, delivering diverse recycling strategies for a greener future.