TEL: +86-177 3033 8505 EMAIL: info@cnwali.com

Contact |

Waste Plastic

Plastic, the material that has transformed modern life, also poses unprecedented environmental challenges. According to Greenpeace, by the 1950s, humanity had produced approximately 9.2 billion tons of this material. In 2019 alone, global plastic production reached 368 million tons, yet only 9% was recycled.

WALI Plastic Recycling Solutions employ high-efficiency crushing technology to process waste plastic into fine granules. These recycled plastic particles can serve as a high-quality asphalt modifier or be repurposed as high-purity recycled raw materials, contributing to resource circularity.

Find the right shredder

Industrial & Commercial Waste Shredders

Single Shaft Shredder

Blade diameter

220-400mm

Capacity

0.2-1.2 t/h

Driving power

18-90 kw

Application

Metal Hammer Mill

Blade diameter

520-1000 mm

Capacity

1-50t/h

Driving power

200-450 kw

Application

Projects

professional team improve the advanced technical support

SHREDDING OF COMMERCIAL AND INDUSTRIAL WASTE

Perfect solution & advantages

Technical Advantages

1. Customizable single shaft shredder

√ Equipped with a screen to control the discharge

√ Square high-alloy steel blades arranged in a V-shape enhance crushing efficiency, durability, and allow multiple adjustments.

√ Equipped with auto-reverse system, which re-orients rotor direction when motor overload or material jam.

2.Smart Control System

√ Siemens PLC with real-time monitoring

√ Fully automated operation with energy optimization algorithms

3.Low operation and maintenance cost

√ With a rational design, plastic single shaft shredders are simple to operate and maintain.

Comprehensive Solutions and Outstanding Service

Your Partner for Personalized Recycling Solutions and Comprehensive Services

I. Custom Turnkey Solutions

The system is engineered to shred plastic into smaller fragments for easier recycling, transportation, and reprocessing.

√ Capacity:1-3t/h

√ Main shredder: single shaft shredder

√ Application: plastic bottles, plastic pallet,etc.

II.Custom Turnkey Solutions

√ End-to-End Processing Lines

Flexible configuration, can be equipped with different equipment according to the final application and production requirements.

√ One-Stop Service

Engineering support + installation + operator training

Top brand quality at a competitive price. For everyone!

We would be happy to put you in touch with competent and reliable financing partners to assist you with the financing of your recycling machine.

We would be pleased to help you free of charge and without obligation.

Find the right shredder

Further products

Discover the full range of products

Scrap Metal

This system aims to break down items containing metal into smaller pieces in order to recover and reprocess ferrous metals from the materials, ensuring maximum metal recovery and minimizing resource waste.

Waste Plastic

This system breaks down plastic into smaller pieces for easier recycling, transportation, and reprocessing. And it reduces landfill waste, lowers disposal costs, and supports a circular economy by re-purposing plastic into new products.

Waste Tyre

This system is designed to recycle waste tires, automatically separating rubber, steel wires, and nylon fibers, transforming “black pollution” into high-value resources. It offers an eco-friendly solution with economic benefits.

Municipal Solid Waste

If the existing model continues without seeking breakthroughs and innovations, it will not only result in significant resource waste but may also trigger more serious problems, ultimately affecting the quality of life and health security.

About Us

We have been persisting in this field for 20 years.

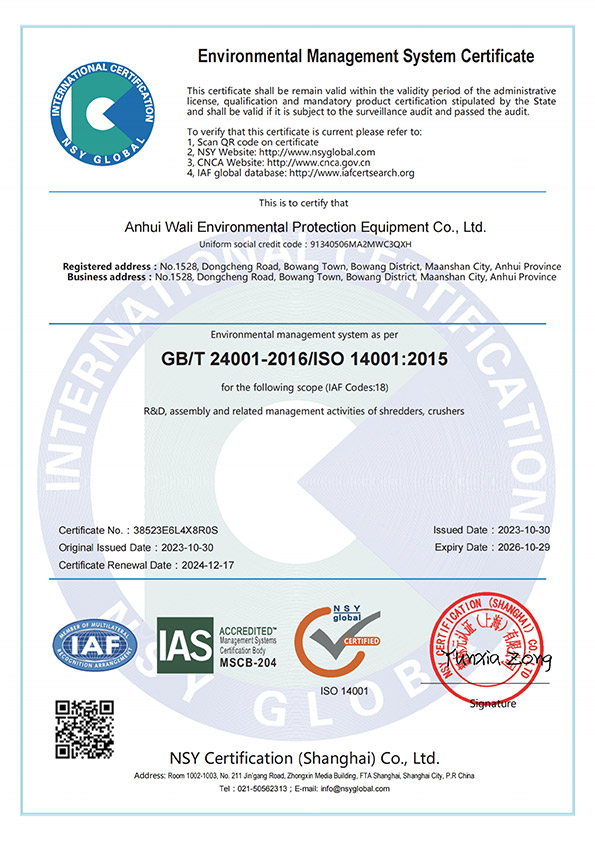

Certificates

The following are our certificates.