TEL: +86-177 3033 8505 EMAIL: info@cnwali.com

Kontakt |

Scrap Metal

Laut Statistik, Weltweiter Stahlverbrauch erreicht 1.85 Milliarden Tonnen in 2023, Aluminiumverbrauch überschritten 70 Millionen Tonnen, und die Kupfernachfrage erreichte einen historischen Höchststand von 28 Millionen Tonnen.

Aber, Es ist alarmierend, dass die derzeitigen weltweiten Metallrecyclingquoten im Allgemeinen niedrig sind – etwa 85% für Stahl, 60% für Aluminium, und sogar weniger als 20% für seltene Metalle.

Wali metal recycling line utilizes a combination of sorting and magnetic separation processes to achieve precise segregation of various metals (e.g. ferrous metals, non-ferrous metals like aluminum)

Find the right shredder

Industrial & Commercial Waste Shredders

Doppelwellen-Aktenvernichter

Blade diameter

215-430 mm

Fassungsvermögen

0.5-4 t/h

Driving power

22-90 kW

Anwendung

Metall-Hammermühle

Blade diameter

520-1000 mm

Fassungsvermögen

0.3-12 t/h

Driving power

22-27 kW

Anwendung

Kettenförderer

Geschwindigkeit

0-20 m/min

Effective width

2000 mm

Driving power

3 kW

Anwendung

Gurtförderer

Geschwindigkeit

48 m/min

Effective width

1200 mm

Driving power

3 kW

Anwendung

Projekte

Professionelles Team verbessert den erweiterten technischen Support

SHREDDING OF COMMERCIAL AND INDUSTRIAL WASTE

Perfect solution & advantages

Technical Advantages

1. Dual-shaft shredder

√ Equipped with high-torque capabilities, it performs pre-crushing of materials.

2. Hammer crusher

√ Processes pre-shredded metal by further crushing and compacting it, while removing surface contaminants and separating metals for sorting.

3. Magnetic separator

√ Used for ferrous metals. This device efficiently recovers iron-based materials after they are crushed by the hammer crusher.

4. Eddy current separator

√ Used to sort non-ferrous metals, such as aluminum and copper.

5. Dust removal system

√ Collects dust generated during the crushing process through an air duct system.

Comprehensive Solutions and Outstanding Service

Your Partner for Personalized Recycling Solutions and Comprehensive Services

Ich. Technical Advantages

Metal recycling system crushes metal-containing items to recover ferrous metals, maximizing recovery and reducing waste.

√ Capacity: 2-3t/h

√ Application: scarp iron,iron drums, Aluminiumdosen, wires & Kabel, printers, display screens, usw.

Ii. Exceptional Service

1.Custom Turnkey Solutions

√ End-to-End Processing Lines

Flexible configuration, can be equipped with different equipment according to the final application and production requirements.

√ One-Stop Service

Engineering support + installation + operator training

Top brand quality at a competitive price. For everyone!

We would be happy to put you in touch with competent and reliable financing partners to assist you with the financing of your recycling machine.

We would be pleased to help you free of charge and without obligation.

Find the right shredder

Further products

Discover the full range of products

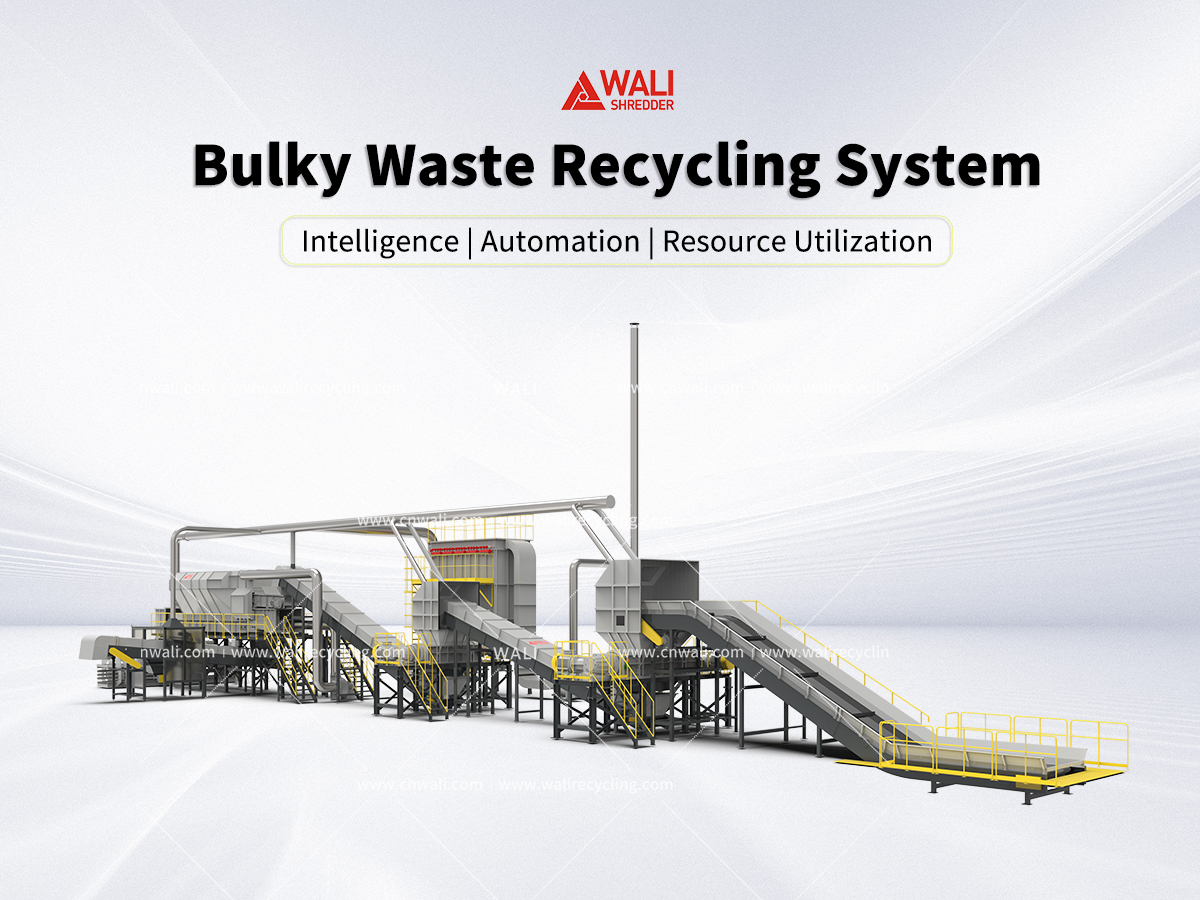

Sperrmüll

Bulky waste contains various valuable resources.

With proper material preparation and advanced system technology, these materials can be efficiently recovered and reintroduced into the raw material cycle.

Scrap Metal

Dieses System zielt darauf ab, metallhaltige Gegenstände in kleinere Stücke zu zerlegen, um Eisenmetalle aus den Materialien zurückzugewinnen und wieder aufzubereiten, Gewährleistung einer maximalen Metallrückgewinnung und Minimierung der Ressourcenverschwendung.

Waste Plastic

This system breaks down plastic into smaller pieces for easier recycling, transportation, and reprocessing. And it reduces landfill waste, lowers disposal costs, and supports a circular economy by re-purposing plastic into new products.

Waste Tyre

This system is designed to recycle waste tires, automatically separating rubber, steel wires, and nylon fibers, transforming “black pollution” into high-value resources. It offers an eco-friendly solution with economic benefits.

Über uns

We have been persisting in this field for 20 years.

Zertifikate

The following are our certificates.