TÉL: +86-177 3033 8505 EMAIL: info@cnwali.com

Contact |

Municipal Solid Waste

Against the backdrop of rapid societal development, global municipal solid waste (MSW) generation continues to rise sharply, reaching approximately 2.4 billion tons in 2023, with an annual growth rate of 2%–3%. Traditional disposal methods such as landfilling and incineration are increasingly inadequate to address the mounting waste management challenges, exacerbating the imbalance between supply and demand.

WALI Intelligent MSW Recycling Solution innovatively adopts a “two-stage crushing + multi-layered sorting” processus. By leveraging AI-powered sorting technology, it significantly enhances recycling efficiency and enables high-yield resource recovery, offering a breakthrough in tackling the global waste crisis.

Find the right shredder

Industrial & Commercial Waste Shredders

Double Shaft Shredder

Blade diameter

330-650 MM

Capacité

2-25 t/h

Driving power

60-400 kW

Application

Single Shaft Shredder

Blade diameter

220-400 MM

Capacité

5-18 t/h

Driving power

110-500 kW

Application

Convoyeur à chaîne

Vitesse

0-20 m/min

Effective width

2000 MM

Driving power

5.5-15 kW

Application

Projects

L’équipe professionnelle améliore le support technique avancé

SHREDDING OF COMMERCIAL AND INDUSTRIAL WASTE

Perfect solution & advantages

Technical Advantages

je. Primary Crusher

√ Features high torque, energy efficiency, strong stability, and impact resistance for coarse crushing of materials.

Ii. Magnetic Separator

√ Used to extract ferrous metals, efficiently recovering iron-based materials from municipal solid waste (MSW).

III. Star Screen

√ Classifies materials by size, separating them into oversize (screen rejects) and undersize (screen fines).

Iv. Air Separator

√ Separates lightweight materials (Par exemple, matière plastique, papier) from heavy materials (Par exemple, métal, verre) using airflow.

V. Single-Shaft Shredder

√ Performs fine shredding to further reduce material size for downstream processing.

Comprehensive Solutions and Outstanding Service

Your Partner for Personalized Recycling Solutions and Comprehensive Services

je. Custom Turnkey Solutions

The system adopts an integrated processing model of “two-stage crushing + multi-layered sorting” to achieve volume reduction treatment,while separating recyclable materials for resource recovery and laying the foundation for subsequent SRF/RDF production.

√ Capacity: 30-40t/h

√ Application: Municipal Solid Waste, etc..

Ii. Custom Turnkey Solutions

√ End-to-End Processing Lines

Flexible configuration, can be equipped with different equipment according to the final application and production requirements.

√ One-Stop Service

Engineering support + installation + operator training

Top brand quality at a competitive price. For everyone!

We would be happy to put you in touch with competent and reliable financing partners to assist you with the financing of your recycling machine.

We would be pleased to help you free of charge and without obligation.

Find the right shredder

Further products

Discover the full range of products

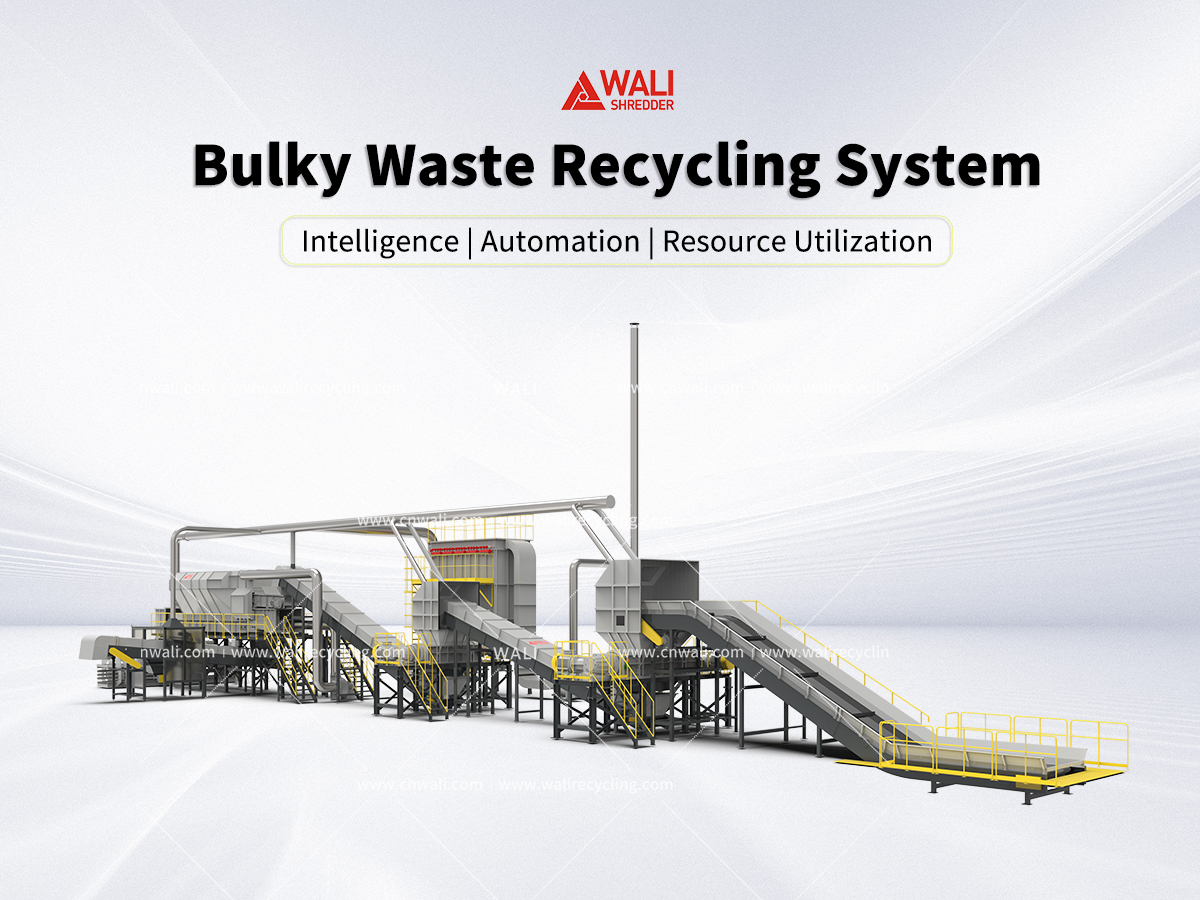

Déchets encombrants

Bulky waste contains various valuable resources.

With proper material preparation and advanced system technology, these materials can be efficiently recovered and reintroduced into the raw material cycle.

Waste Tyre

This system is designed to recycle waste tires, automatically separating rubber, steel wires, and nylon fibers, transforming “black pollution” into high-value resources. It offers an eco-friendly solution with economic benefits.

Waste Plastic

This system breaks down plastic into smaller pieces for easier recycling, transportation, and reprocessing. And it reduces landfill waste, lowers disposal costs, and supports a circular economy by re-purposing plastic into new products.

Municipal Solid Waste

If the existing model continues without seeking breakthroughs and innovations, it will not only result in significant resource waste but may also trigger more serious problems, ultimately affecting the quality of life and health security.

À propos de nous

We have been persisting in this field for 20 années.

Certificats

The following are our certificates.