Scrap Cars & Tire

With over 1.4 billion vehicles on the road globally, more than 10 million cars are scrapped each year, making them one of the fastest-growing waste streams.These end-of-life vehicles hold significant resource potential—a typical passenger car is 75% metal by weight, including 65% steel and 10% алюминий. Studies show that recycling just 1 ton of scrap steel reduces CO₂ emissions by 1.5 tons, offering major environmental benefits. Однако, improper disposal not only harms the environment but also wastes large amounts of recoverable metals.

WALI scrap car solutions ensure higher metal purity, lower energy consumption, and greater profitability for auto recyclers worldwide.

Find the right shredder

Промышленный & Commercial Waste Shredders

Двухвальный измельчитель

Blade diameter

330-650 миллиметр

Способность

2-25 т/ч

Driving power

60-400 Квт

Application

Metal Hammer Mill

Blade diameter

520-1000 миллиметр

Способность

0.3-12 т/ч

Driving power

22-27 Квт

Application

Проекты

Профессиональная команда улучшает расширенную техническую поддержку

SHREDDING OF COMMERCIAL AND INDUSTRIAL WASTE

Perfect solution & advantages

The Wali End-of-Life Vehicle Shredding and Sorting System is a specialized equipment designed for crushing and recycling scrapped car bodies and waste metals.

Technical Advantages

1.Automotive-Optimized Shredders

√ High-torque, low-energy consumption design

√ Customizable tooling: Specialized blade geometries for different metals (steel/aluminum/copper)

√ Premium alloy steel blades: longer lifespan, quick-change mounting system

2.Smart Control System

√ Siemens PLC with real-time monitoring

√ Fully automated operation with energy optimization algorithms

3.Advanced Separation Technology

√ Combined air separation + magnetic/eddy current systems,ensuring metal purity

Comprehensive Solutions and Outstanding Service

Your Partner for Personalized Recycling Solutions and Comprehensive Services

Я. Custom Turnkey Solutions

1. End-to-End Processing Lines

√ Custom configurations: From dismantling → shredding → separation → baling

2. One-Stop Service

√ Engineering support + installation + operator training

Глава II. Industry Leadership

1.50+ successful deployments across automotive, e-waste, and metal recycling sectors

Глава III. Global Support Network

1. 24/7 multilingual technical support

2. Guaranteed 72-hour on-site response for critical issues

Top brand quality at a competitive price. For everyone!

We would be happy to put you in touch with competent and reliable financing partners to assist you with the financing of your recycling machine.

We would be pleased to help you free of charge and without obligation.

Find the right shredder

Further products

Discover the full range of products

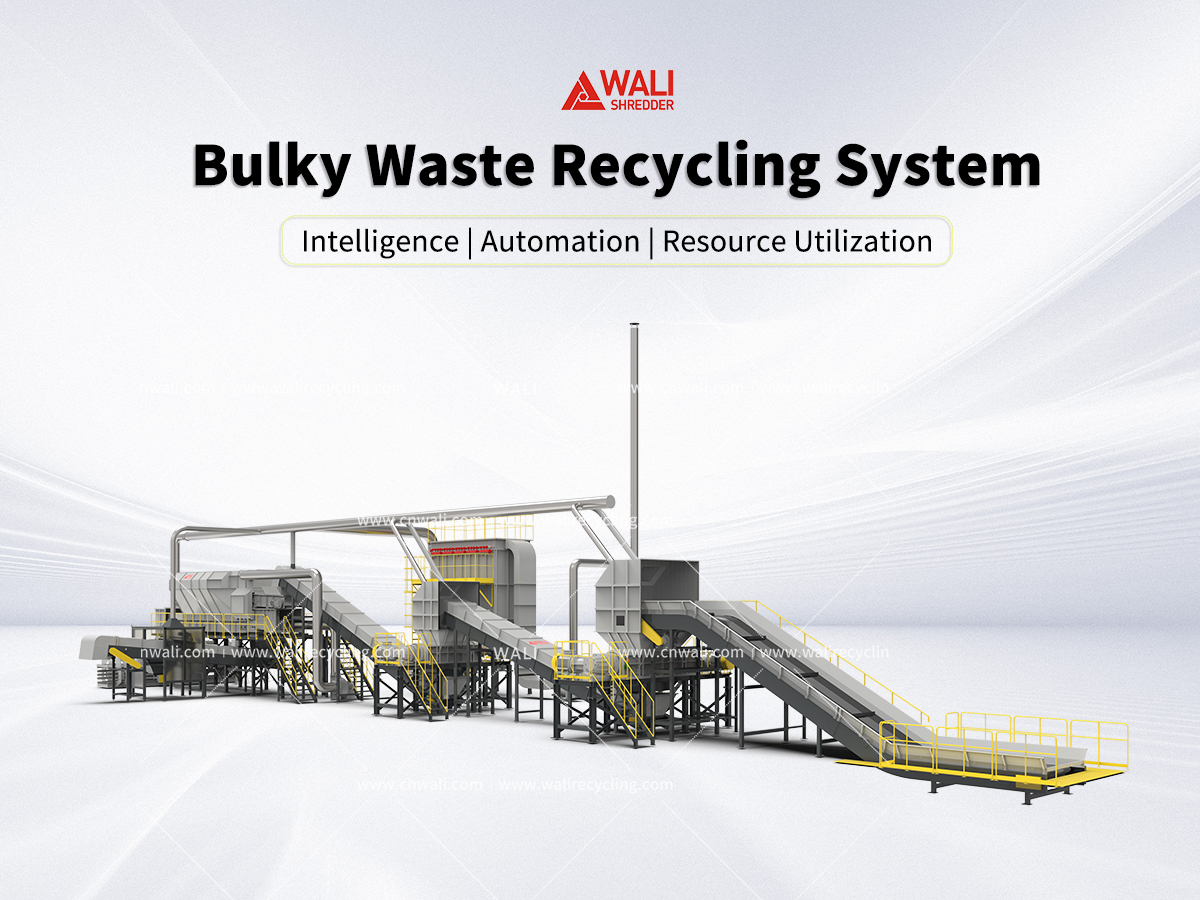

Крупногабаритные отходы

Bulky waste contains various valuable resources.

With proper material preparation and advanced system technology, these materials can be efficiently recovered and reintroduced into the raw material cycle.

Primary Crusher

The important device used in this project is robust double -shaft shredder. It is a heavy-duty double shaft shredder machine with large throughput specially designed for crushing various packaging bags, including plastic bags.

Four shaft shredder

Four-shaft shredder is a device to reduce waste materials to homogeneous particle sizes whether as a stand-alone solution or as part of recycling system. It is designed for crushing Barrel products,Solid waste, и так далее.

Municipal Solid Waste

If the existing model continues without seeking breakthroughs and innovations, it will not only result in significant resource waste but may also trigger more serious problems, ultimately affecting the quality of life and health security.

О нас

We have been persisting in this field for 20 years.

Сертификаты

The following are our certificates.