โทร: +86-177 3033 8505 EMAIL: info@cnwali.com

ติดต่อ |

มวลชีวภาพ

Biomass energy utilization is a key sector in renewable resource development.Through systematic collection, crushing, and efficient conversion, biomass materials such as agricultural and forestry waste (เช่น, straw, wood chips, fruit shells) and energy crops can be transformed into biomass pellet fuel, biogas, or combined heat and power (CHP) energy.

Wali Intelligent Crushing and Sorting System delivers specialized pre-treatment solutions. With high-capacity crushing and impurity separation, it provides homogenized raw materials for biomass power plants, gasification projects, and solid fuel production lines. This enhances conversion efficiency for biomass energy enterprises, driving the sustainable transition of agricultural and forestry waste into clean energy and circular economy applications.

Find the right shredder

Industrial & Commercial Waste Shredders

Double Shaft Shredder

Blade diameter

330-650 มม.

ความสามารถ

2-25 t/h

Driving power

60-400 กิโลวัตต์

แอปพลิเคชัน

Single Shaft Shredder

Blade diameter

300-370 มม.

ความสามารถ

300-1000 kg/h

Driving power

11-30 กิโลวัตต์

แอปพลิเคชัน

สายพานลําเลียงโซ่

ความเร็ว

0-20 ม/ของฉัน

Effective width

2000 มม.

Driving power

5.5-15 กิโลวัตต์

แอปพลิเคชัน

สายพานลําเลียง

ความเร็ว

48 ม/ของฉัน

Effective width

1200 มม.

Driving power

3-7.5 กิโลวัตต์

แอปพลิเคชัน

Projects

ทีมงานมืออาชีพปรับปรุงการสนับสนุนทางเทคนิคขั้นสูง

SHREDDING OF COMMERCIAL AND INDUSTRIAL WASTE

Perfect solution & advantages

Technical Advantages

1. Customizable single shaft shredder

√ Equipped with a screen to control the discharge

√ Square high-alloy steel blades arranged in a V-shape enhance crushing efficiency, ความทนทาน, and allow multiple adjustments.

√ Equipped with auto-reverse system, which re-orients rotor direction when motor overload or material jam.

2. Smart Control System

√ Siemens PLC with real-time monitoring

√ Fully automated operation with energy optimization algorithms

3. ต้นทุนการดําเนินงานและการบํารุงรักษาต่ํา

ด้วยการออกแบบที่มีเหตุผล, เครื่องทําลายเพลาเดี่ยวใช้งานง่ายและบํารุงรักษา.

Comprehensive Solutions and Outstanding Service

Your Partner for Personalized Recycling Solutions and Comprehensive Services

ฉัน. Custom Turnkey Solutions

The system adopts an integrated processing model of ” crushing + sorting” to achieve precise crushing, while separating recyclable materials for resource recovery.

√ Capacity: 1-20t/h

√ Main shredder: double shaft shredder

√ Application: crop straws (wheat/rice/corn stalks), sugarcane bagasse, wood chips and other lignocellulosic residues

ครั้งที่สอง. Custom Turnkey Solutions

√ End-to-End Processing Lines

Flexible configuration, can be equipped with different equipment according to the final application and production requirements.

√ One-Stop Service

Engineering support + installation + operator training

Top brand quality at a competitive price. For everyone!

We would be happy to put you in touch with competent and reliable financing partners to assist you with the financing of your recycling machine.

We would be pleased to help you free of charge and without obligation.

Find the right shredder

Further products

Discover the full range of products

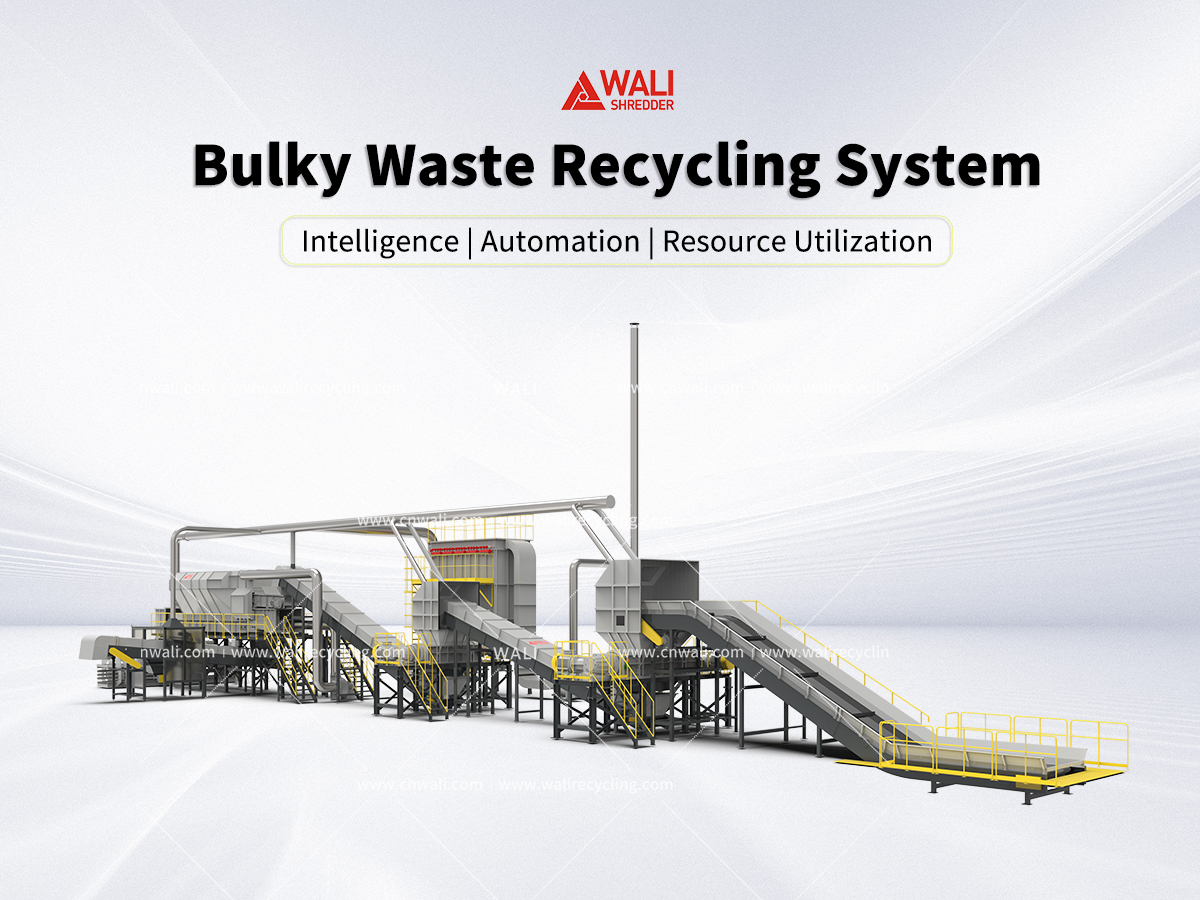

ขยะขนาดใหญ่

Bulky waste contains various valuable resources.

With proper material preparation and advanced system technology, these materials can be efficiently recovered and reintroduced into the raw material cycle.

Waste Tyre

This system is designed to recycle waste tires, automatically separating rubber, steel wires, and nylon fibers, transforming “black pollution” into high-value resources. It offers an eco-friendly solution with economic benefits.

Waste Plastic

This system breaks down plastic into smaller pieces for easier recycling, transportation, and reprocessing. And it reduces landfill waste, lowers disposal costs, and supports a circular economy by re-purposing plastic into new products.

Industrial Waste

Wali Industrial Waste Recycling System utilizes an advanced two-stage crushing process to process high-calorific solid waste, achieving a final particle size of 30-80mm (adjustable as required) with a compliance rate exceeding 95%.

เกี่ยวกับเรา

We have been persisting in this field for 20 ปี.

ใบ รับรอง

The following are our certificates.